Mecal News

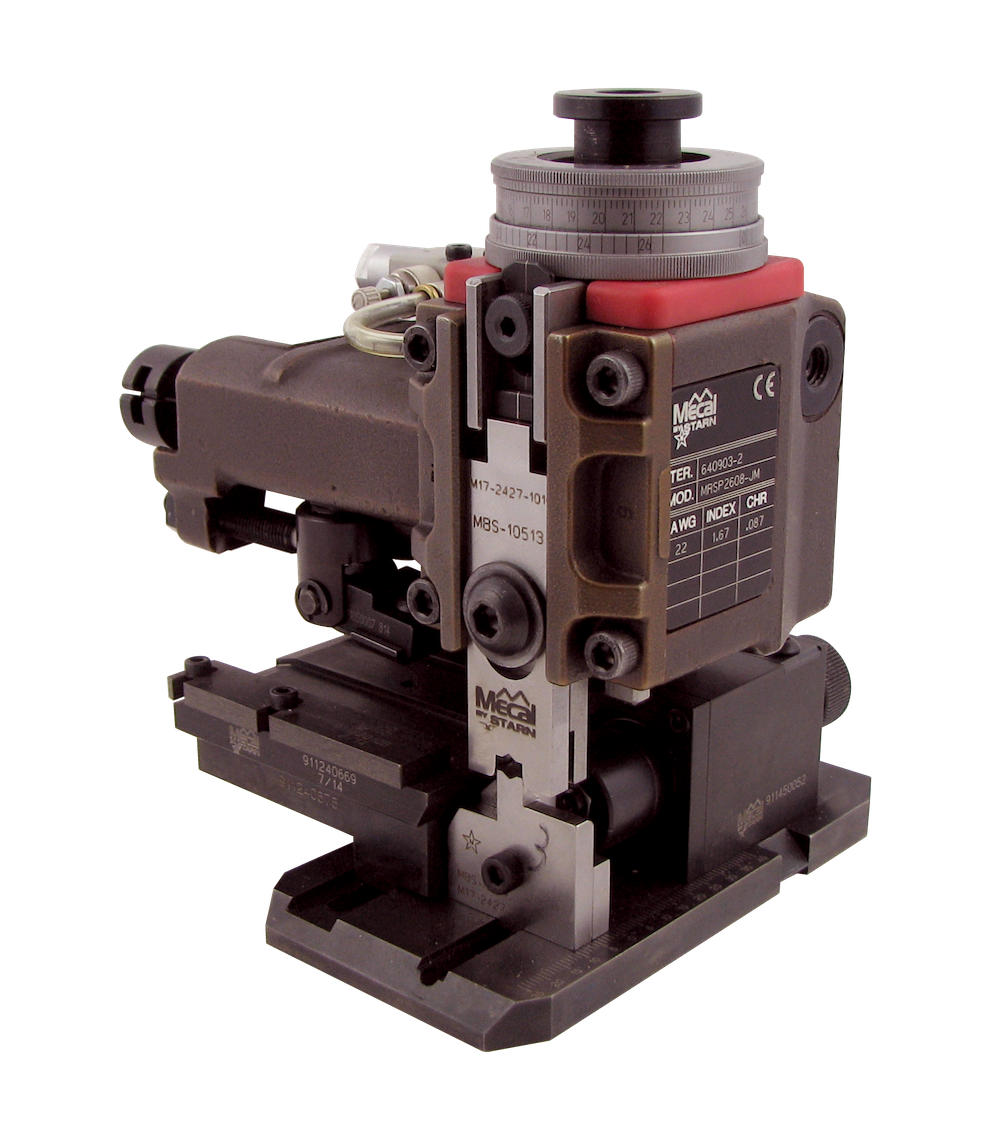

What Comes with an MBS Applicator?

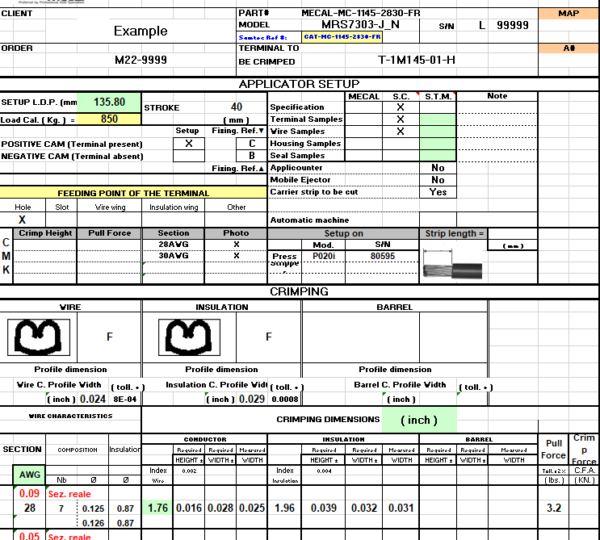

Quality Documentation

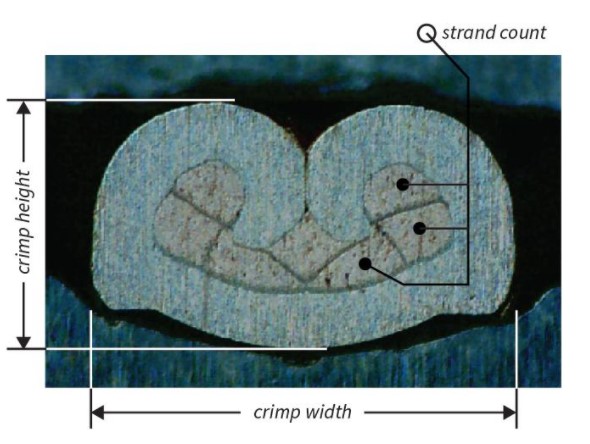

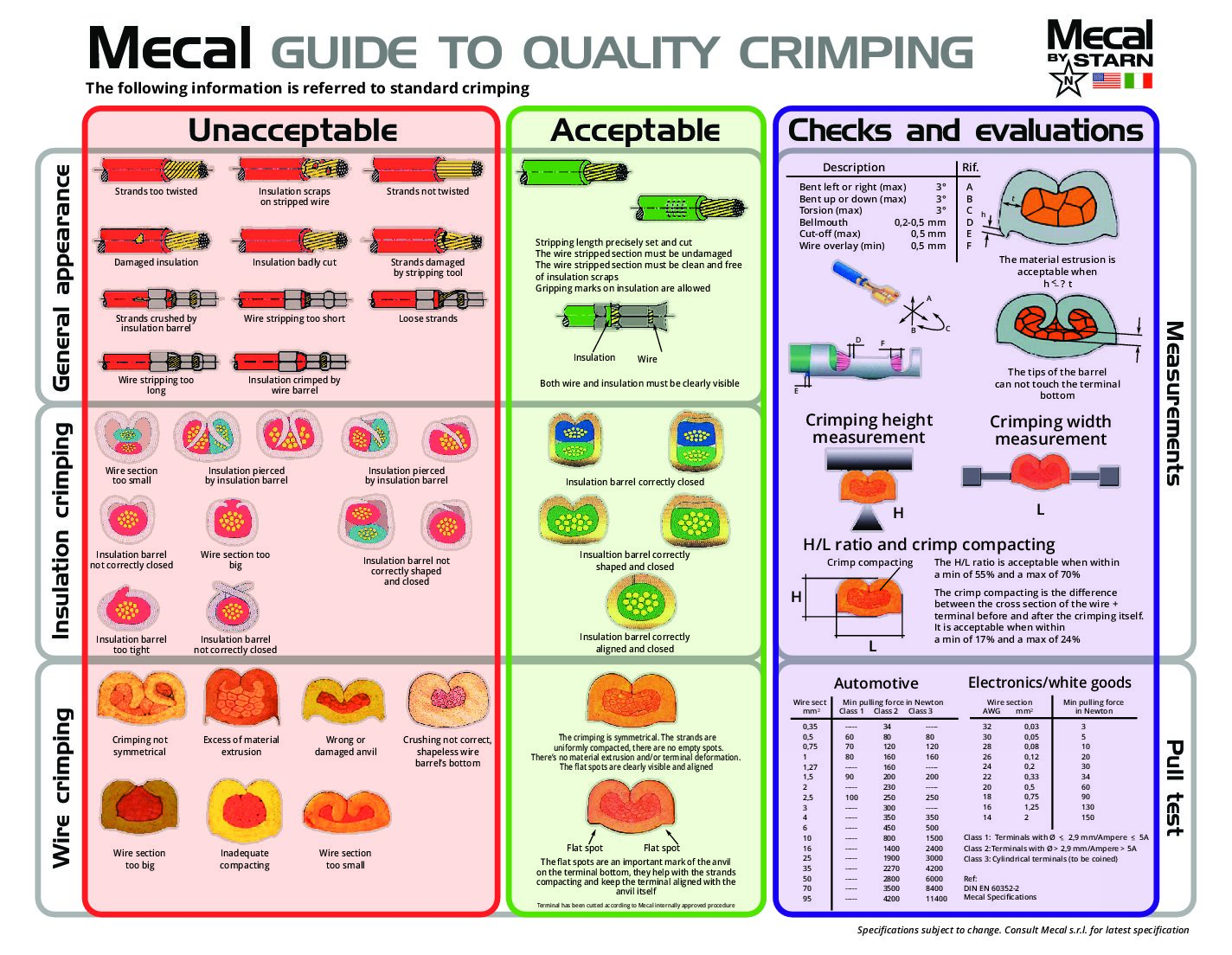

Documentation ensures consistency, efficiency, quality and standardization. This includes a bill of materials, an exploded parts view with detail numbers, cross-section images, pull tests report, and (5) sample leads. These documents allow you to verify crimp height & width, pull test, and compression ratio, and easily find any part numbers that you may need to replace. BOM Tab Documentation Explanation

Reliably Ready

Our applicators are assembled and validated at our Meadville, Pa location. They come out of the box ready to crimp with little-to-no adjustments. When assembling the applicators, our technicians validate them through several tests & inspections. This includes a cross-section analysis, pull test verification, and a comprehensive quality inspection. The comprehensive quality inspection includes:

The comprehensive quality inspection includes:

- Burr

- Number of Strands

- Crimp Height & Width

- Cut off tab

- Terminal Bend & Twist

For more on our quality inspection, learn about it here

For more on our quality inspection, learn about it here MECAL BY STARN OFFERS

Presses ranging from 1.5 to 20 ton capabilities.

Mecal By Starn Sales

Mecal By Starn started as a partnership between Mecal and Starn Tool in order to supply North American Wire Harness Industry with world-class applicators, presses and spare parts from Mecal. Mecal was established in 1976 with the aim of supplying the wire harness industry with the best crimping equipment available. While Starn Tool, a well-respected precision machining company since 1945, has supported the wire harness industry since the 1960’s.

Today, Mecal by Starn is known for its customer service excellence across its expansive product line, as well as innovation and capability in custom-designed solutions to meet customer needs and help solve complex project challenges.

Mecal News

Join us at EWPTE 2025

Meet Mauricio Valdebenito

Perishable Tooling & Reverse Engineering Solutions

WANT TO GET STARTED?

Talk to One of Our Experts